3D Printing is surely a big revolution for the 21st century.Changing the lives of the people it has impacted all the industries in some or the other ways. This vast industry also has some misconceptions that are still not clear to people. Whether you are pro or a beginner, some of the misconceptions still remain behind our minds.

Let’s know what these misconceptions are:

3D Printers are too expensive

This depends on what you intend to do in the 3D printing industry. If you want to grow a business around it than investment is worth. Yes, there are a lot of high priced printers, but that involves what you determine to print, the size of the object, which type of filament will be used, the speed of the printer, various features etc.

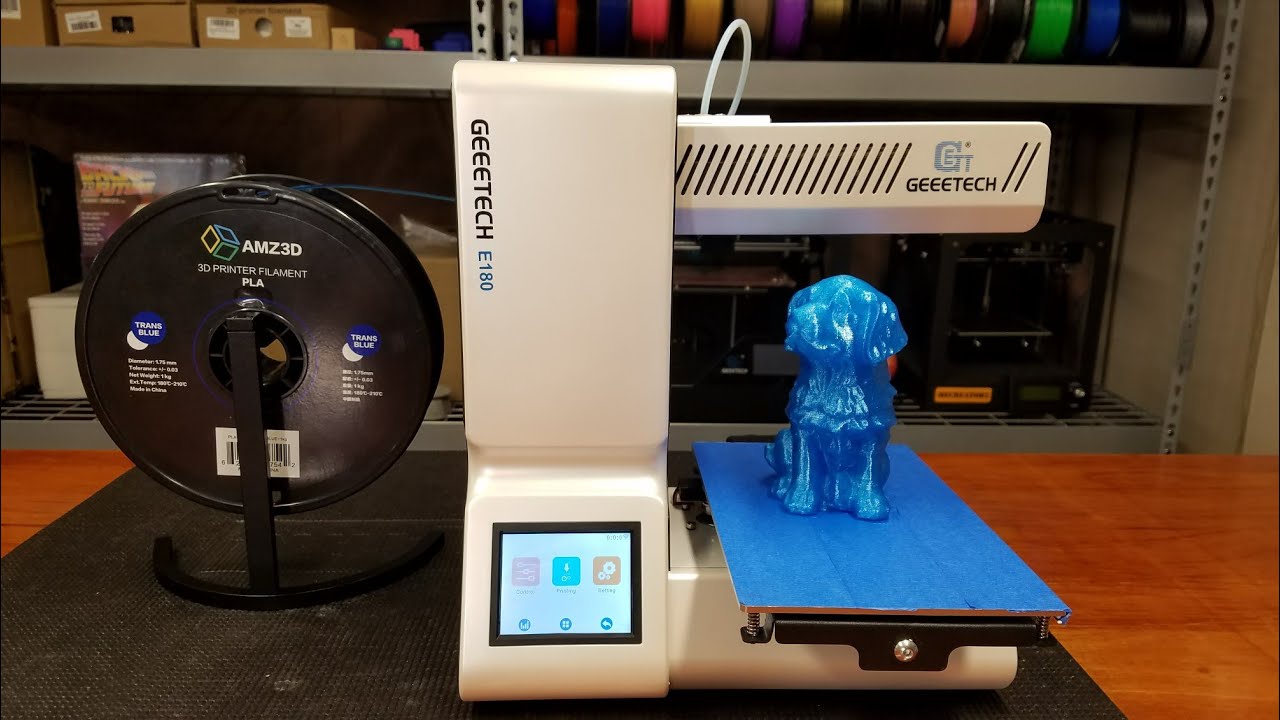

You need to collect proper information about the printer and what you aim at printing. Thus a plan is required and then the budget summary if you want to buy a printer. There are 3D Printers which cost less than the price of a laptop like Geeetech E180 Mini wifi 3D printer just at $298.

The E180 lets your children print large sized models by breaking them down into chunks. You can’t print the important machine parts but surely as hobbyists, you can find printers with a varied range of price.

3D Printing is Magic

No No No!!! 3D printing surely isn’t any magic, it’s just additive manufacturing. When you start printing with one of the printers you will feel as if you are in first-year class in the Hogwarts school basically in the potions class. It is learning that matters. Knowing your printer well and the filaments it supports, what settings will work better, how to adjust speed and other software settings etc.

Know that patience is the key to 3D Printing because sometimes the prints will come really easy and perfect and sometimes you will face the problems of warping, stringing and lot more. You can read and know more about the troubleshooting issues on our Geeetech blog.

Failures at 3D printing do not mean that you are not good at it, even the experienced people end up with failed prints, and the causes range from damp filament to a not-sticky-enough build surface to a tiny flaw in the model to a printer that’s just being really, really crabby for no good reason.Some printers do give a smooth print and no post-processing is required but certain objects do require to work on after the build comes off the platform.

It can Print Perfect Pizza!!!

3D printing is over exaggerated as to anything and impossible things can be 3D printed. Surely you cannot 3D print a Pizza which is perfect as the one we get in Dominos, but there are companies like BeeHex, who are hardworking to print a perfect pizza.

While making the pizza they can’t 3D print the vegetables and meat, the soft base could be 3D printed and as heard it is pretty delicious too. They use these Food printers to make candy that shapes like your face, or potato chips etc. 3D Food printing can take over the industry in the future and its gonna become a serious business.

Bonus: It’s like Star Trek

The “Replicators” from Star Trek are probably hard to develop and thus 3D printing is misconceived by many users. Though 3D printing is the future, there cannot be objects produced by pure energy and thin air as in Star Trek.

3D printers are large they require large filaments and manufacturing materials to print out an object and so need space. We also won’t 3D print a working phone, laser pistol or TV remote, because printers can’t (at least yet) use conductive materials to manufacture cables and electronics.

3D printing will take over Manufacturing

That’s not true, you cannot possibly print everything with a 3D printer. This is the hyped misconception about 3D printing. We do come across people saying how additive manufacturing has helped them grow and saved their time also increased the business in manufacturing, but they are basically talking about prototyping.

Prototyping is a time-consuming step in manufacturing where the copy resembling how the final product is shown, which has to be first designed and finalized then sent to the production team to produce. The final product is the replica of the prototype designed having different measurements, but before that, if the product produced needs modifications the whole process starts again.

With a 3D printer, companies can design a part in CAD software, print it out in a matter of hours, and often test it the same day. Then if changes are required, modify the digital model, print it out again, and continue until the part has been perfected, for no more cost than the price of the filament.

Now when you know about the misconceptions regarding 3D Printing you are ready to start with 3D Printing the small stuff and read the tips and tricks to perfectly print 3D objects with our Geeetech 3D printers.

Credits: 3dprint.com,all3dp.com,medium.com,youtube.com,businessinsider.com,gizmodo.com

No comments:

Post a Comment