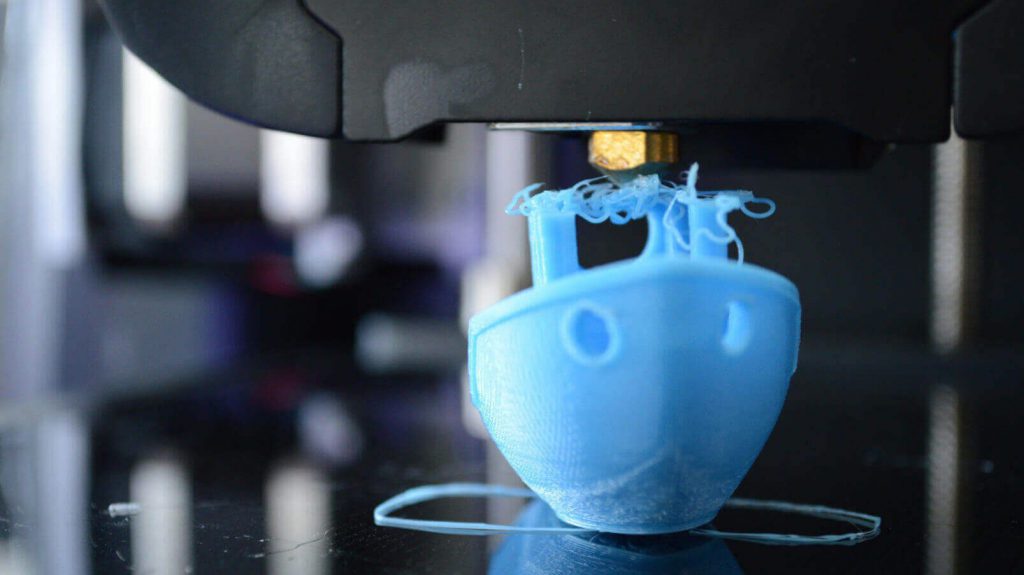

Let’s be honest- 3D printing isn’t as easy as it looks. Especially if you’re a beginner, there are many problems that you will encounter but that shouldn’t stop you from pushing on. One of the most common 3D printing problems that we face is when your print stops right in the middle and you’re left confused wondering what went wrong. Sounds like something you’ve experienced? Read on for some simple solutions!

The 3D Printing Problem-

You’re in the middle of a print when suddenly the extruder stops printing and your work is left incomplete.

Why does it happen?

If you’re wondering if something is wrong with your 3D Printer then calm down. There are a few major reasons why a print will stop mid-way and all of them can be solved very easily. The problem lies either with the filament or the nozzle. In many cases, we simply run out of filament or face an issue with the current filament but aren’t aware till the print stops. If it’s not the filament then double check to see if the nozzle is blocked. Here are few ways to fix the problem:

1. Check if you’ve run out of filament

The first thing to check if your print randomly stops is if you have enough filament. Many times we forget that we’re coming to the end of a spool and that there isn’t really anything wrong with your printer. Just feed your extruder a new spool of filament and carry on with your print. Alternatively, you can use a slicer which will give you a material estimation for your prints. All it does it judge the weight of your spool of filament and tells you if there’s enough filament to complete your print.

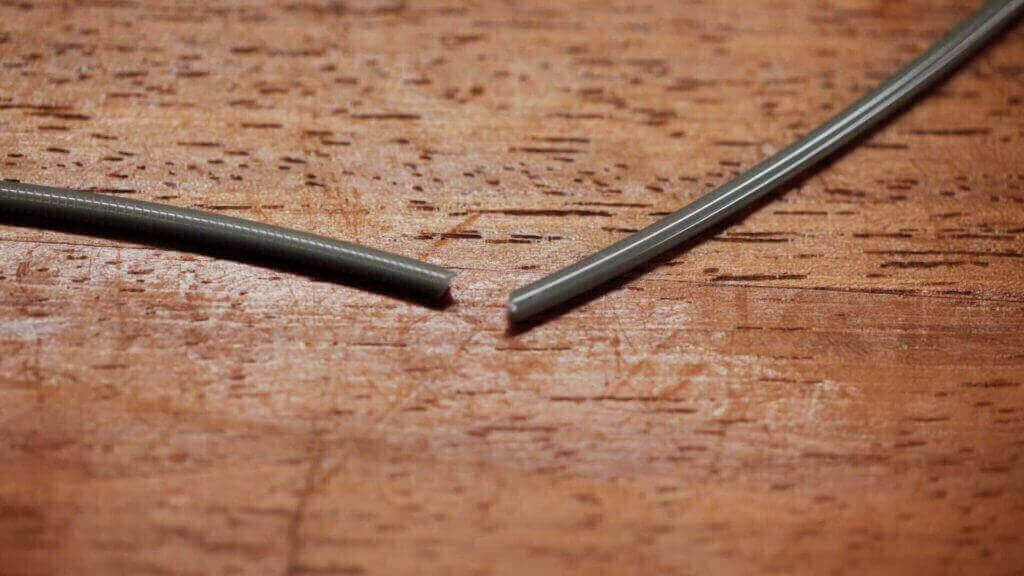

2. Did your filament snap?

Filament usually only snap if they are old or have been incorrectly stored which makes them brittle. To make sure you’re keeping your filament stored in the best way check out our guide- An Easy Way To Store Your 3D Printing Filament

If you think your filament is in good condition then check the filament diameter as sometimes the diameters can vary which increases the tension. You can reduce the idler tension if it’s too tight by loosening it.

3. Is your filament stripped?

Stripping of filament is another reason why your extruder stops printing. You can try reducing the retraction and speed setting as well as increasing the temperature by 5-10 degrees. Another reason why your filament can strip is due to a blocked nozzle.

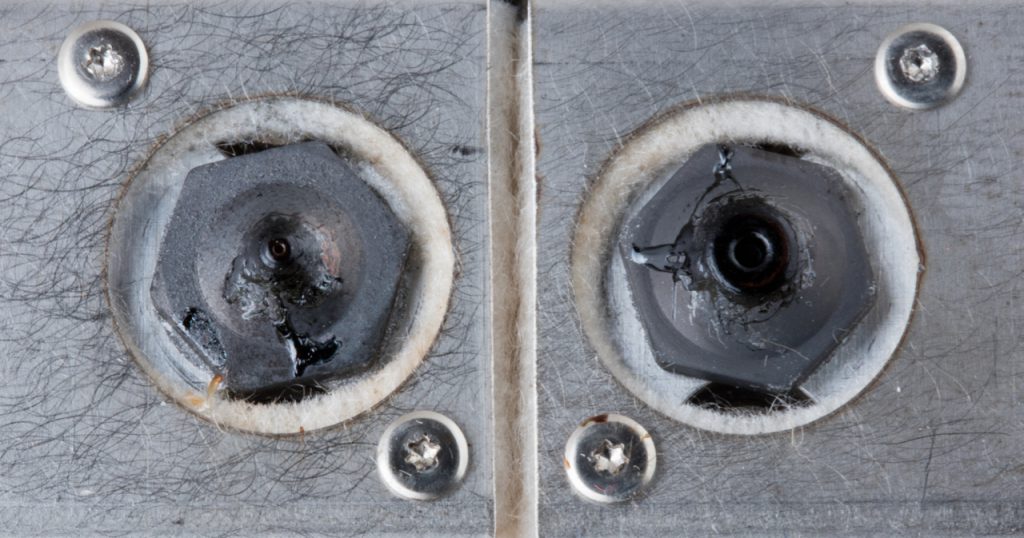

4. Check if your nozzle is blocked

If you constantly switch between filaments like PLA or ABS then there are higher chances of your nozzle getting blocked. A small amount of filament gets left behind which causes it to harden up and when this keeps happening, you’ll find that even though you have sufficient filament, none of will be pushed out through the nozzle. Take a look at our easy guide to fix your Blocked Nozzle.

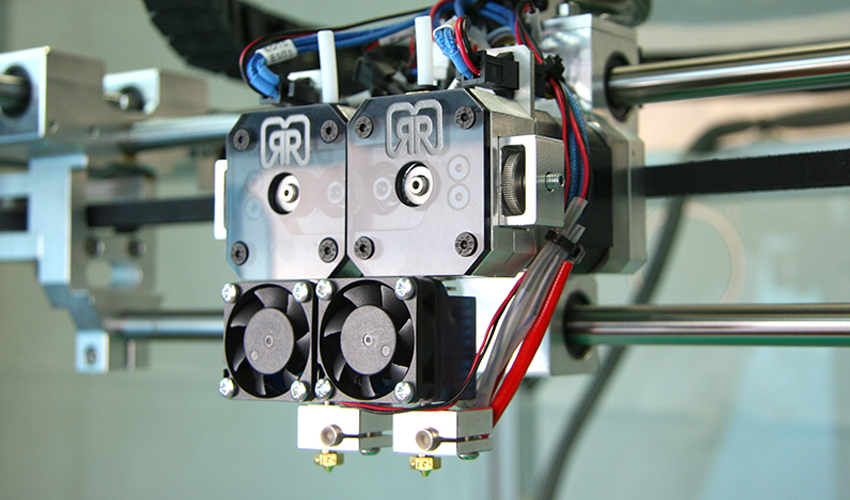

5. Check if the extruder is over-heated

With the extruder doing all the hard work, it’s very common for it to heat up excessively during a print. The constant constantly back and forth movement for hours at a stretch can cause the extruder motor to overheat, especially if there isn’t sufficient cooling. Since they have a thermal cutoff, your extruder will stop working in the middle of your print if the temperature gets too high. The only way to resolve this issue is to turn off the printer and allow the electronics to cool down. To avoid the problem completely try adding an extra cooling fan.

If you found this guide helpful, share it with your friends to help them out!

Credits: all3dp.com, support.markforged.com, 3dnatives.com

No comments:

Post a Comment