3D Printing is certainly having a lot of impact on our lives, exploring creativity and awesomeness but after every print, there is an extra filament left and oozing out which has to be trimmed.This filament cannot be used again as it is too small.Think about how many 3D printers there are in the world and how many things they’re printing every day, and that’s a whole lot of waste that can only really end up in a landfill.

The biggest environmental issue is to tackle the plastic waste. Plastic has been accumulated on our earth since it was discovered and there is no way out to get rid of it, an alarming sign of pollution now. But it can be recycled and reused, so the better way out of this pollution problem is 3D Printing.

We cannot stop utilizing plastic but surely can make the most of it by recycling it…

Read the stories below to know how to efficiently use the wasted plastic while 3D Printing:

Precious Plastic Project

As the name suggests Precious Plastic is the global community of environment lovers who look forward to ending the plastic pollution. Here anyone can share their collaborative techniques and ideas.Already many people are working towards reusing the old plastics and make creative useful products.

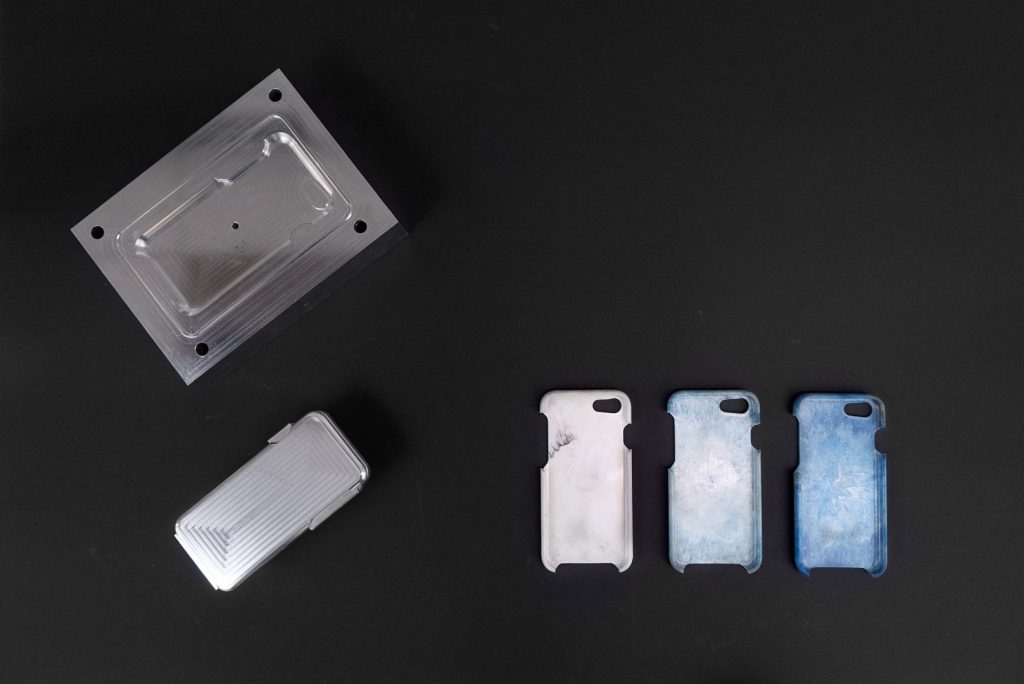

Currently, the team is turning otherwise unrecyclable plastic into functional smartphone cases. Anything from old plastic bottles to takeaway cup tops is being combined to create new iPhone cases.Precious Plastic has created a manufacturing ecosystem to help people to turn plastic waste into valuable products.

We previously covered the project during the initial launch of its open source production platform.The company also gives a toolkit and machinery including a plastic waste shredder, an extrusion machine to create 3D printing filaments from recycled plastics, an injection molder, as well as a compressor to help process the molds. To check the efficiency of these tools they are creating iPhone covers as the first project from recycled plastic.

Reform the campus

UC Berkeley is a leader in 3D printing has students all over the campus printing their favorite things and exploring which also creates a lot of plastic waste.Almost over 600 pounds trash is generated all over. The students Nicole Panditi, and Scott Silva have a solution.

They’re creating a campuswide system that takes used 3D printer plastic, grinds it up, melts it down and produces a new spool of plastic that can be used again in the campus’s 3D printers.

In spite of the fact that there have been a few endeavors to reuse 3D printer plastic on campus and some labs purchase reused fiber, this would be the first run through Berkeley had a framework to reuse all the 3D plastic waste on campus, something Panditi says will be fundamental as 3D printing turns out to be increasingly well known.

From Plastic Bottles

Three engineering physics students at the University of British Columbia in Canada have developed the ProtoCycler, a gadget that can crush a wide range of waste plastic into an excellent clean spool of plastic fiber that can be utilized as a filament of a 3D printer.

We’re talking anything – plastic jugs, 3D-printing shorts, takeaway nourishment compartments. In the event that your children forget their LEGOs one too often for you to tread on with your uncovered feet… toss them in as well. It works simply like a juicer, which you can find in the video.

Sustainability is what we all are striving for. We can surely lend help to keep the earth pollution free by whatever means we can. Even if its a small thing it matters a lot. Plastic cannot be eradicated but better used, so making the most of it is in our hands.

Start with a small change and see how the world changes. A push towards 3D Printing and the better world starts here at Geeetech. Join us to make the world a better place to live in.

Credits: perpetualplasticproject.com,all3dp.com,youtube.com,news.berkeley.edu,sciencealert.com.

No comments:

Post a Comment